COLLABORATIVE INNOVATION

David Moses is a motivational leader who develops and deploys customized B2B product and system solutions

As the Founder of Express Business Forms & Systems in the 1990's, and then transitioning to XpresspaX, Inc. in 2000, David has worked with numerous clients for over 30 years with exceptionally positive results. As an example, this single project below brought authentic, lasting change and value to each of these companies, employees and end-users.

From the $100M/year supplier

“David brings so much energy and enthusiasm to the table. He has a unique ability to challenge the status quo and the teams’ conclusions to see if there might be a better method, more economical option or improved design. David was also the first to express his sincere gratitude for our employee’s extra efforts through awards, personal recognition and appreciation lunch events. This motivated our team to achieve more for our collective benefit.”

From the $4B/year customer

“Using one word to describe Dave Moses – “transformational”. I have known and worked with Dave for more than 20 years where he supplied services, products and consulting advice to my organization. His ideas, solutions and results truly changed not only our company, but the entire industry, and added real customer value.”

From the competitor

“Our significant resources were no match against Dave’s perseverance and ability to overcome tough competition…”

We evaluate your business processes with an end-to-end lens to focus the organization on transforming challenges into innovative opportunities, creating authentic economic and social value to employees, customers, and stakeholders.

Almost every aspect of life has changed over the last few years. One thing that hasn’t changed is your need to get the job done – better, faster, stronger – but with very limited resources. What you need is Dave!

Available for Full-time or Fractional / Interim Executive Positions for driving revenue and operational efficiencies through process and product improvement.

I’m not going to just point you in the right direction; I’m going to walk there with you.

Listen to this podcast interview with Dave talking about developing and delivering creative solutions.

OPPORTUNITY passes very quickly!

Seizing it takes valuable resources – money, intention, time, and energy. Are you ready?

- Your company is lean, and your resources leaner!

- You need to make strong decisions for Business Process Improvement and Business Process Outsourcing.

- You need to optimize product portfolio management, driving cost-saving opportunities and improved customer relations.

- Your sales team needs motivation and guidance to successfully sell higher-value solutions.

- Your supply chain is not delivering what you need when you need it.

- You are a young company that has a great idea and need strong guidance to deliver your product or service to market.

While authentic change doesn’t happen easily, our game-changing philosophy of energetic motivation creates stronger business processes, improves critical relationships, and helps drive revenue.

David is a proven innovator with over 30 years of experience successfully directing process improvement and manufacturing projects for $1M to $500M companies, achieving exceptional gains in revenue, earnings, sustainability, and relationships.

David's Executive Attributes

- Strong financial and strategic skills

- Team Builder

- Strong Negotiator

- Emotional Intelligence

- Entrepreneurial and vision-oriented

- Experienced in manufacturing and service industries

Assess, Innovate, Optimize

Critical, in-depth study of current business processes and products. New process development is all-encompassing to reach full integration and deployment.

Identifying and realizing high-value process innovation opportunities that improve profitability, safety, and efficiencies while increasing core corporate value.

Taking Form, Fit and Function to the next level. Utilizing:

- Design-For-Manufacture

- Design-For-Assembly

- Design-For-Repair

to improve adaptation, resource optimization, sustainability, and to reduce obsolescence.

Which comes first – the process, or the product?

- Whether your need is a process improvement, or a product improvement, we combine our entrepreneurial passion for collaboration and innovation to achieve meaningful change.

- We facilitate diverse enterprise-level strategic partnerships, from the customer and end-users, through the supply partners, providing an End-to End solution.

- David is agnostic to the raw materials or manufacturing processes utilized to create or improve products, and remains focused on the stated mission, avoiding “scope creep”.

- After an initial discovery and review phase, you can expect a roadmap that charts a clear and efficient course from vision through creation, deployment, and review.

David holds Scrum Master and Scrum Product Owner certifications, utilizing team-building Agile methodologies where applicable, and has also studied Entrepreneurial Operating System (EOS).

Listen to this podcast interview with Dave talking about developing and delivering creative solutions.

Clients and Testimonials

David created and delivered a completely new product line for a major division of our company that nobody internally ever would have been able to develop.

CUSTOMER-JP, Product Life-Cycle Management Director

Game Changers

Through our innovative efforts to solve problems and provide solutions, many customers have improved operations, increased revenue and added long-term value to customers, employees and stakeholders. Here are just a few of the game-changing successes that transformed the business processes, products, and the industry.

Which comes first – the process or the product?

In this case, the customer demanded a new product line, which when deployed, yielded a massive Business Process Improvement that netted huge savings and efficiencies.

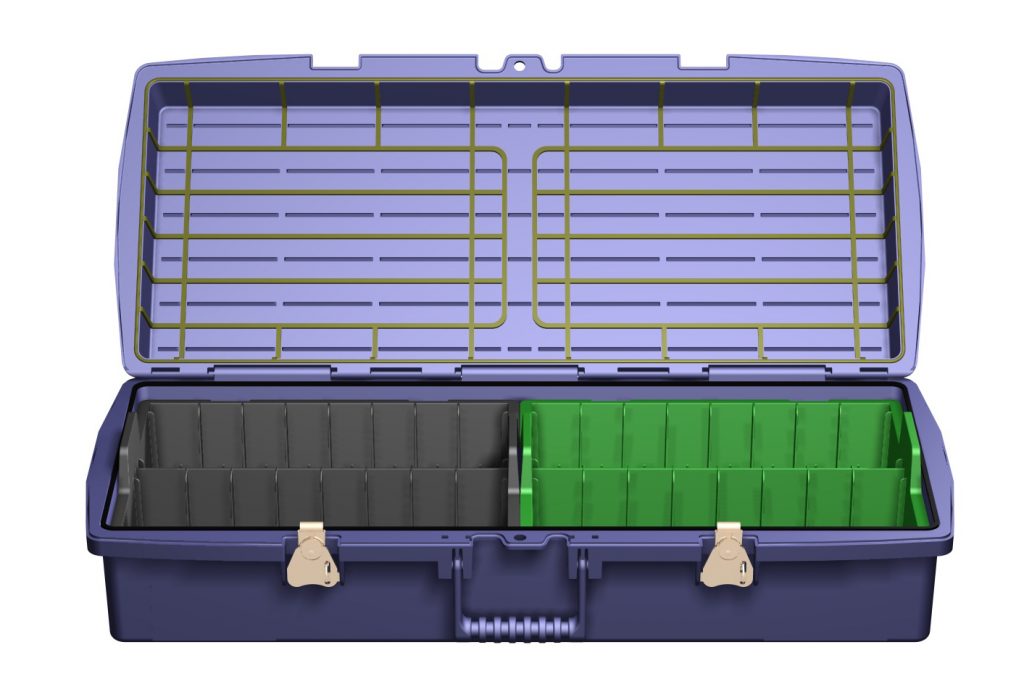

Iron Mountain, one of the world’s largest off-site data protection companies, required a completely new design of the container system at the core of their end-to-end offsite media transportation and storage supply chain. The challenge Iron Mountain faced was that the existing industry containers and cases were not adequately ensuring the level of security and integrity required for the various backup data tapes, drives, laptops and other computer peripherals and devices.

Iron Mountain required a new, best-in-class global standard that would measurably reduce the chances for data losses, while also improve their status as the premier brand in the data protection market.

At the time, across multiple locations in North America, and some global facilities, the customer was using up to 50 different data storage containers of various shapes, sizes and materials. This lack of standardization also created considerable wasted space in very expensive storage vault racking facilities. Those widely ranging shapes and sizes also made it difficult to accurately manage and audit space consumption by container, resulting in poor revenue management per storage area.

David designed and ultimately manufactured a unique three-unit secure plastic container system with interchangeable media-specific insert trays that provide a new standard of multi-point security for the supply chain, while also dramatically elevating the customer’s brand loyalty and sales metrics.

The new container system provided the customer with the ability to more densely pack their data vaults, knowing exactly how much space was being consumed by every container, which in turn drove revenue higher. The standardized containers allowed the customer to create racking products designed around the XpresspaX container system, improving vault density even more. Additionally the modular Design-For-Assembly approach for the system, with interchangeable media-specific storage trays, significantly minimized obsolescence compared to the competitors products, greatly reducing costs and excess inventory issues. As the customer grew domestically and globally, XpresspaX distributed the container system to nearly all international locations, which allowed the customer to provide a standardized solution to their demanding global customers as well.

The XpresspaX container system has become the global standard for most of the world’s largest data-creators including Google, IBM, Apple, YAHOO, and many more. The revenue improvement for this customer over the 20 years of the program, with containers that will remain in usage for many more years, is greater than $20,000,000.00. As the current EVP recently stated, “The container system David designed was an absolute homerun!”

Which comes first – the process or the product?

In this case, the customer needed both, a product that improved efficiencies and mitigated serious injuries and turnover. This new design delivered both in dramatic fashion.

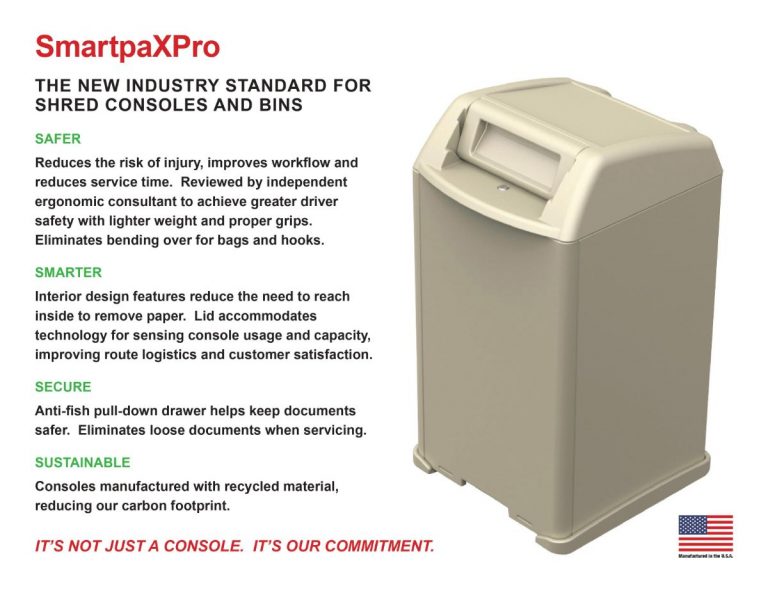

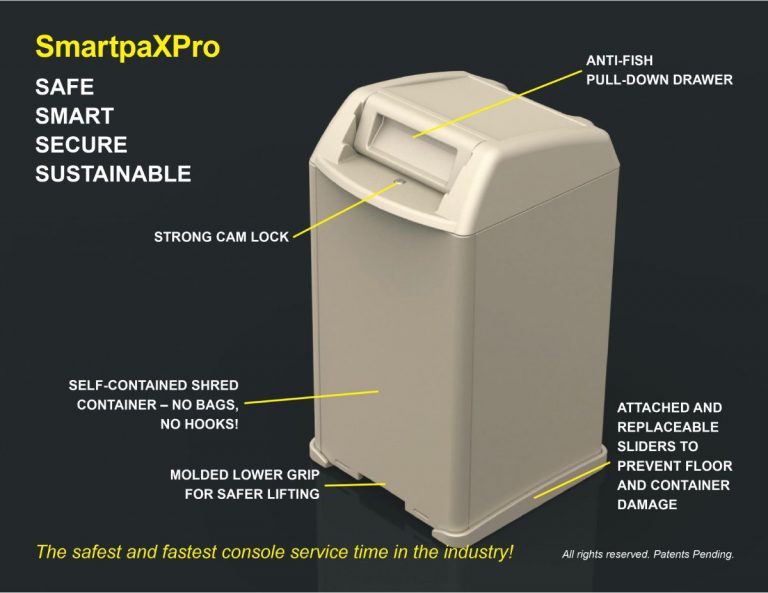

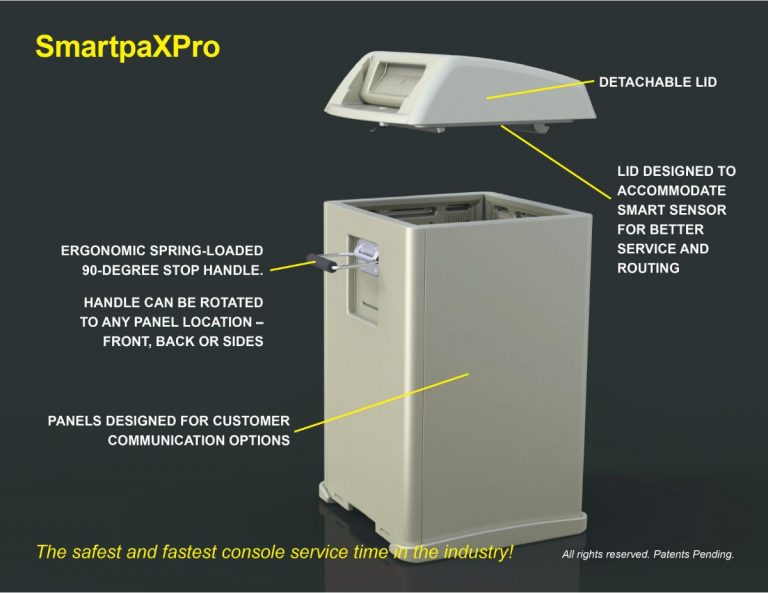

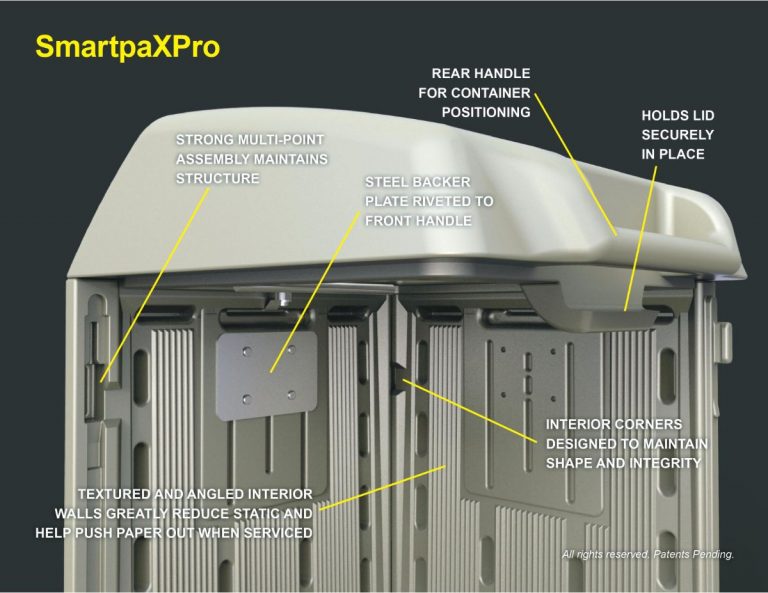

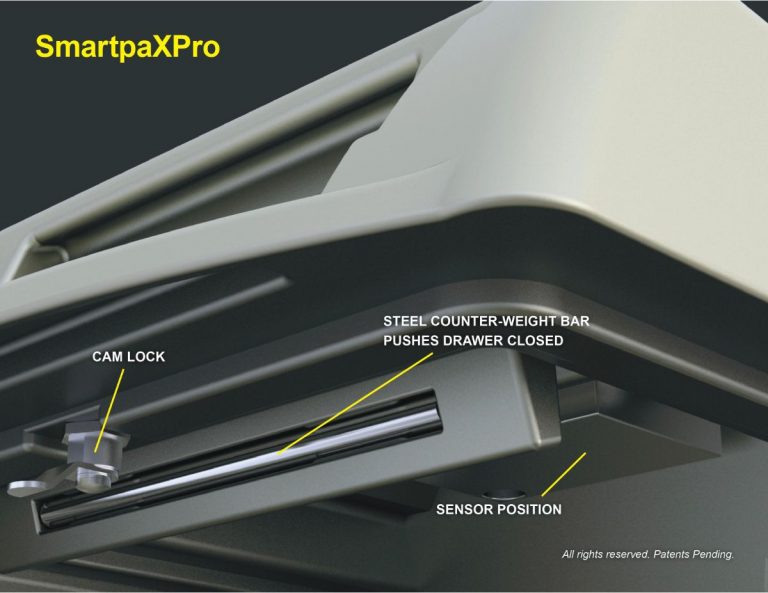

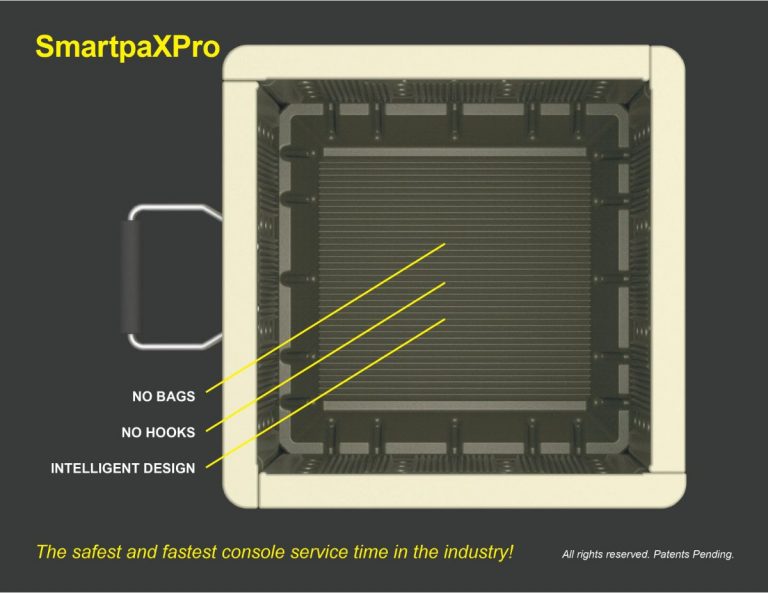

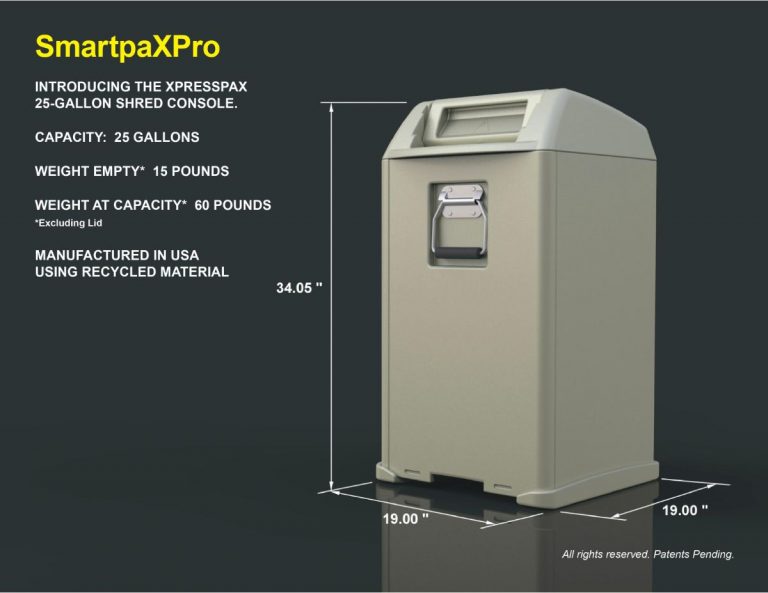

One of the largest document shredding companies in North America was seeking to improve their business process with a proprietary line of shred receptacles designed to securely contain documents throughout their life-cycle from office collection points and then transported to off-premise shredding facilities.

The existing industry product offerings were essentially large-wheeled trash barrels or low-quality particle-board consoles that had not been measurably improved in decades. These products were responsible for a very high employee injury rate, were limited by slow processing times, incurred significant waste and replacement costs, and lacked any features or benefits that our client/customer could uniquely “brand” as their own. After several RFP’s to suppliers for improved designs and functionality, no proposals were received that offered significant or valuable product improvements. When the customer finally contacted David, their clear statement was – “We never want to buy another single unit of what we are currently using!”.

The customer asked David to analyze the existing product landscape, typical workflow and user behaviors, and then design and develop a new line of products that would reduce the risk of injuries, increase efficiencies, and ideally also address future sustainability concerns. Over the next 18 months of industry R&D, and substantial analysis of the customer’s facilities, vehicles and practices, David presented a novel design with options for substantial advancement in safety, performance and profitability.

The customer ordered third-party ergonomic testing with side-by-side time/motion studies comparing the legacy system to the proposed XpresspaX system, where it was determined that the XpresspaX system would reduce employee injuries by as much as 70%, improved productivity by as much as 83%, reduce employee turnover by 50%, with an overall projected annual savings by converting to the new system of as much as $25,000,000.

David was issued patents on the new shred receptacle program in 2021.

Which comes first – the process or the product?

In this case, the customer needed a new process to accurately identify millions of transient items. The newly developed Process Improvement also yielded an integrated on-demand barcode form/label system, which grew beyond the customer’s internal ability. With Business Process Outsourcing, the customer greatly improved customer service, revenue and employee morale.

A major global records management company with rapid growth required a new barcode tracking system for hundreds of thousands of inventory assets. This business process improvement required that David design and produce unique barcode labels coupled with data collection forms that captured the barcode on each piece, for product identification and chain of custody throughout the storage/retrieval process, and years-long life of the assets. This program required broad database management of highly confidential data, a print-on-demand solution, desktop distribution services, and a significant incremental reporting schedule for accountability of millions of labels generated each year.

In the first two years of this program, David created and deployed a service-level opportunity that exceeded all previous performance metrics for the direct client (customer), on behalf of dozens of their end-customers. Over the ensuing 13 years, thousands more end-customers benefitted from the fully optimized system capable of tracking and delivery of a wide range of vital records. The program consistently delivered an increase in year-over-year volume efficiency, catalyzed by a process that accurately labeled, securely transported and safely stored product, with all data entry points verified by the new barcode label system.

The new process streamlined the voluminous workflow and allowed for a faster initial revenue stream for the acquired units, ultimately reducing operational expenses and increasing profitability, with a net improvement of over $10,000,000.

Gallery

Media Storage Containers

Modular best-in-class container and insert tray system is utilized by most of the largest companies in the world to transport and store back-up data tapes and drives. The system is the result of a new product created based on the customer’s need for Business Process Improvement.

Shred Bin and Console

Manufacture-For-Assembly multi-size secure document receptacle, improving efficiency and sustainability, while greatly reducing the risk of serious injury.

Additional Projects

Customized clothing storage wardrobe and foldable secure container for multi-usage.

Work With Us

We specialize in helping B2B and B2C product and service companies that need experience and guidance to improve operational efficiencies and drive revenue. We find that small to mid-sized companies with revenues of $5M to $100M experience the challenges that we are best-suited to address, although many of our largest projects were for global multi-billion-dollar customers.

For clients that need focused attention in a specific senior/executive-level position, a Fractional engagement provides a longer-term opportunity to drive authentic, lasting change for business products and processes. This can be flexible – from a day or two per week, to every other week, or a schedule that fits your specific needs.

For a client that has a senior-level gap due to the Great-Resignation, transitions, or expansion, an Interim option allows us to work together to get the job done until the company has had the opportunity to permanently fill positions as needed.

For clients that have a specific business process or product offering that needs significant overhaul, we can work together based on those project parameters. If you have a product that needs to be re-designed, re-sourced, or fully replaced, we can manage the project from design to delivery, and beyond.

First, it’s important to understand how we charge. Charging by the hour can become an obstacle for working together. We generally work on a project basis that is a fixed-price so you know the costs ahead of time. Once we agree on the value then we can simply concentrate on getting the job done.

Our prices are in line with compensation levels for similar senior team members on the CEO’s staff.

We are open to opportunities that provide some “skin in the game”, including financial investments in the business where applicable, or equity-based performance incentives.